LED Light Strips are known for their durability and energy efficiency, but over time, you might notice issues like flickering, dim sections, or parts not lighting up. Fortunately, most problems can be fixed easily with basic tools and a little patience.

At GMH, we produce high-efficiency LED strip lights that are built to last and easy to maintain. This step-by-step guide will teach you how to fix led light strips safely and effectively — whether for home, office, or commercial use.

Before fixing, it’s important to identify what’s wrong. Here are the most common issues and what usually causes them:

| Problem | Likely Cause |

|---|---|

| LED strip not turning on | power supply issue, loose connection, or polarity reversal |

| Partial section not lighting | Broken circuit, damaged LED chips, or faulty solder joint |

| Flickering lights | Inconsistent voltage or loose connection |

| Color inconsistency | Controller malfunction or mixed RGB channel wiring |

| Dim lights | Power supply too weak or voltage drop over long runs |

| Adhesive not sticking | Dusty surface or worn-out tape backing |

Understanding the root cause helps you apply the right fix — and prevents future issues.

Gather the following tools before you begin:

| Tool | Purpose |

|---|---|

| Multimeter | To test voltage and continuity |

| Scissors / Cutter | For trimming damaged sections |

| Soldering Iron (optional) | To reconnect cut or broken parts |

| LED Strip Connector | Quick-fix option for joining strips |

| Power Supply / Adapter | To replace or test faulty power source |

| Cleaning Cloth & Alcohol Wipes | To clean surface before reinstallation |

| Electrical Tape / Heat Shrink Tubing | To protect exposed joints |

GMH Tip: Always turn off power before working on your LED strip to avoid electric shock or damage.

Make sure the adapter or transformer is plugged in and working.

Use a multimeter to test if the output voltage matches your LED strip rating (e.g., 12V or 24V).

If the voltage is too low, replace the adapter with a compatible GMH power supply designed for LED strips.

Low voltage can cause dim lighting or flickering across the strip.

Disconnect the power.

Check all connectors between the LED strip, controller, and power adapter.

Ensure the positive (+) and negative (–) terminals are correctly aligned.

Re-seat any loose connectors or replace damaged plugs.

Reversed polarity is one of the most common reasons a strip won’t light up.

Look for physical issues such as:

Burned or dark spots on LEDs.

Cracked or bent strip sections.

Loose solder joints or disconnected wires.

Water damage (if the strip isn’t waterproof).

If you find a visibly damaged section, proceed to cut and reconnect it.

If only part of the strip isn’t working:

Identify the faulty section (usually between cutting marks).

Use scissors to cut along the marked cutting line — never cut through LEDs or circuits.

Reconnect the working sections using a clip connector or by soldering.

Using a Connector:

Open the connector’s clip.

Insert both ends of the strip into the connector, aligning the + and – pads.

Close the clip to secure the connection.

Using Solder:

Strip the silicone coating (if present).

Apply a small amount of solder to both pads.

Solder the wires directly to the copper pads, maintaining correct polarity.

Seal the joint with heat shrink tubing or electrical tape for protection.

If your strip flickers or looks dim:

Check if the power supply wattage is sufficient. The total wattage of your LED strip should not exceed 80% of the power adapter’s capacity.

For long strips (over 5 meters), connect additional power feeds at intervals to maintain even brightness.

Inspect the controller (for RGB strips) — sometimes replacing the controller fixes color or brightness irregularities.

GMH Professional Advice: Use a regulated power driver designed for LED strips to maintain stable output and prevent voltage drops.

If your LED strip has peeled away from its mounting surface:

Clean the surface thoroughly with alcohol to remove dust or oil.

Replace the adhesive tape with 3M double-sided tape or use mounting clips for added security.

For heat-sensitive areas, use aluminum channels for better adhesion and heat dissipation.

After making all fixes:

Reconnect the power and test the strip.

Check for consistent brightness, color accuracy, and proper adhesion.

If all sections light up correctly, your repair is complete!

| Tip | Benefit |

|---|---|

| Use the right power supply | Prevents overheating and voltage fluctuation |

| Avoid bending sharply | Protects internal circuits from breakage |

| Install in a ventilated area | Reduces heat buildup and extends lifespan |

| Keep surfaces clean before mounting | Ensures long-term adhesion |

| Use waterproof models for outdoor use | Prevents moisture-related failures |

GMH LED strips are designed with anti-oxidation copper circuits and heat-resistant PC boards, making them more durable under continuous use.

Sometimes, replacement is more efficient than repair.

Replace your LED strip if:

More than 20% of LEDs are burnt out.

The PCB (circuit board) is severely corroded.

The strip has sustained water or heat damage.

It no longer adheres properly even after cleaning.

GMH offers replacement LED strips in various voltages, colors, and waterproof ratings — compatible with most lighting systems.

At GMH, we focus on innovation, efficiency, and reliability in every lighting product we produce.

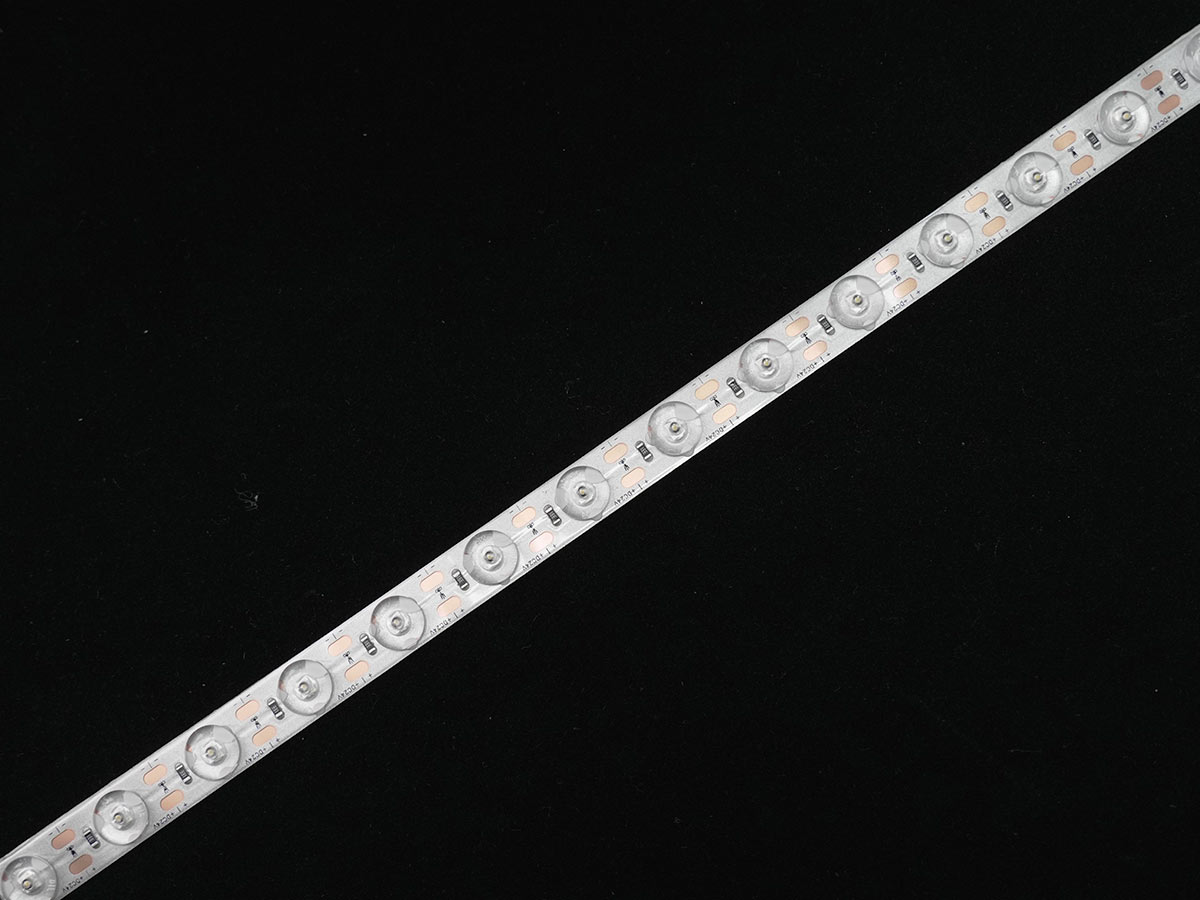

High Efficiency & Brightness: Advanced optical lens modules maximize luminous performance.

Stable Power Delivery: Ensures consistent brightness without flicker.

Flexible Customization: Available in different color temperatures and waterproof ratings.

Global Certification: CE, RoHS, and ISO-compliant manufacturing.

Worldwide Service: Exported to 100+ countries, including Europe, America, and Southeast Asia.

With GMH, you get LED strip lighting designed for performance and built to last.

Fixing your LED strip lights is often quick and straightforward.

Whether you’re reattaching loose connectors, replacing a damaged section, or upgrading your power supply, a careful approach can bring your lighting back to full brightness.

At GMH, we believe that lighting should be both powerful and enduring. Our LED strip lights are engineered for easy installation, simple maintenance, and long-lasting brilliance.

Previous: How To Use An LED Matrix Panel?